Material Handling

Reducing physical workload without losing time

Material Handling

Reducing physical workload without losing time

The essence of our technology is making objects with different masses virtually weightless. Because we are able to compensate for a new weight very fast and with very little energy required, physically taxing labour like the manual picking and placing of goods or objects is an area for which our technology is ideally suited.

Although various lifting aids already exist within this domain, all of these devices have a fundamental flaw, which explains why none of these devices have been widely adopted. For each degree of freedom for which a load is supported by these devices, the operator is required to manipulate the machine via controls in order to move the load. Compared to direct control over the load, as is the case in manual movements, this is very time consuming, and this is costly. In the low margin business, that these industries typically are, this is not a viable option. Our technology however, takes over the weight of the load, while the operator is still in direct control over any movement of the load.

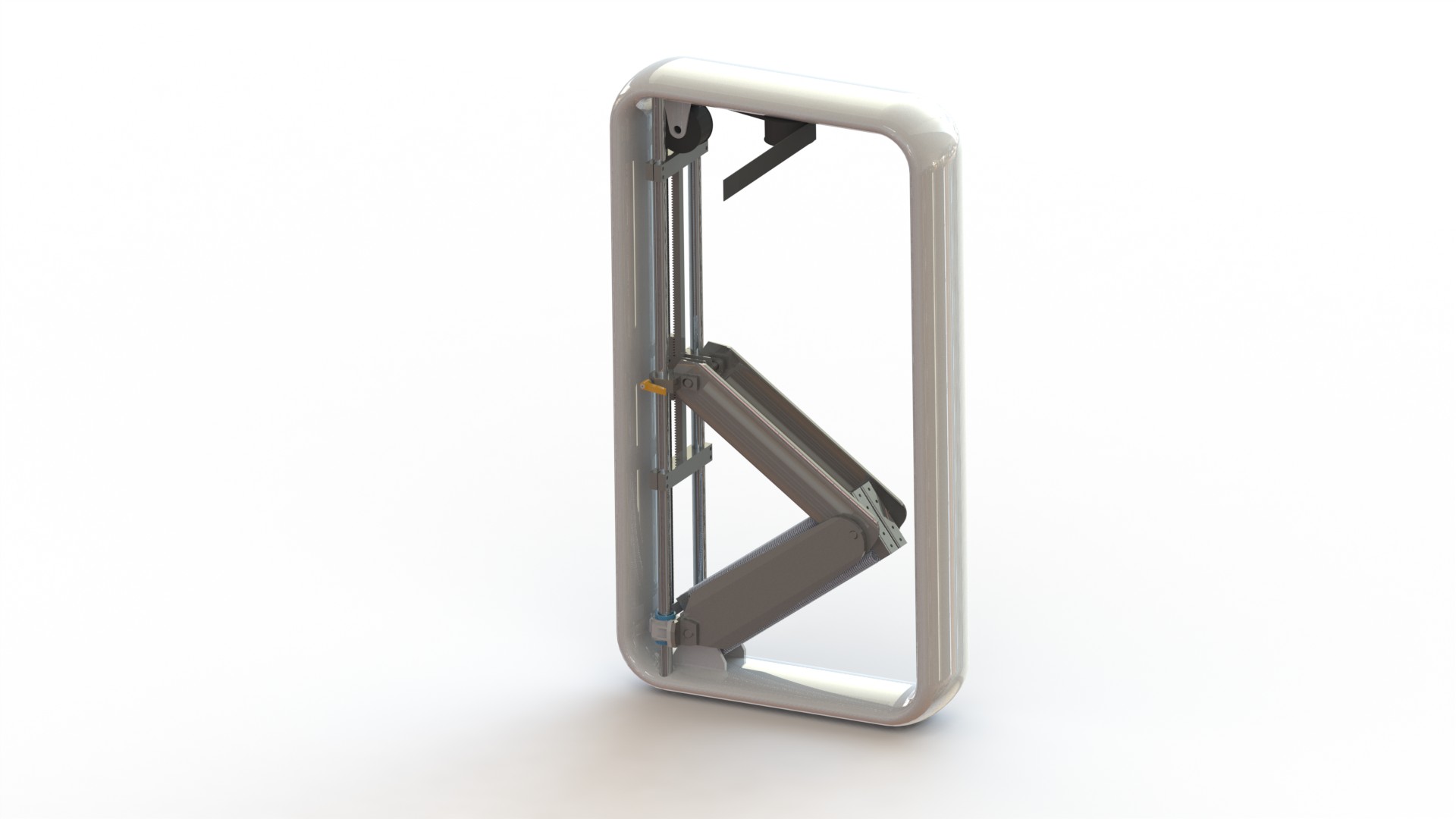

Together with Vanderlande Industries and Type22, NHLO developed a bagage loading aid for loading aircraft containers. This device, that takes the heavy lifting out of loading, enables operators to work faster and be more productive, while their physical workload is strongly reduced. More information about this product can be found here.

STACK@EASE from Vanderlande Industries is a highly flexible loading aid solution that takes the heavy lifting out of loading in baggage handling environments. It helps operators to load containers (ULDs) and carts productively, and minimizes their physical workload -- even over longer working periods.

Offshore

Motion compensation

Offshore

Motion compensation

Since the technology makes an object indifferent of its height within a certain height range, motion compensation is a second domain for which the technology is very well placed.

In cooperation with partners IHC, MARIN and ECN, and partly funded by RVO, numerical models and trials have been sucessfully performed.

For more info, please visit www.seaqualize.com; the offshore daughter company of NHLO.

Industry

Simple tool balancer

Industry

Simple tool balancer

Within assembly lines and workshops, balancers are standard equipment to compensate the weight of for example tools. These balancers have a limited weight adjustment range (typically 10-20%), and have to be adjusted manually in a time consuming manner. With our phantomspring technology it is not only possible to make the balancer self-adjusting, this can also done virtually instantaneous.

Entertainment

Entertainment

Imagine the feeling of being weightless, being able to jump several meters in the air as if you were walking on the surface of the moon. Or Mars for that matter. Wouldn't that be great fun?

Fitness & Wellness

True constant force for safe high-speed weight training

Fitness & Wellness

True constant force for safe high-speed weight training

Several characteristics make PhantomSpring technology exceptionally suitable for implementation in the Fitness

& Wellness industry. Whereas conventional weightlifting machines use pulleys and stacked weights,

clutches, shock absorbers or rubber tension elements to produce resistance, Phantom Spring Technology

(PST) employs a mechanical spring system that duplicates the effect of gravity on stacked weights.

Compressed air systems achieve similar benefits, but also create notable disadvantages. Below you'll find a brief summary of the apparent advantages of PST compared to existing technologies.

SAFE

Weight based machines produce inertia effects that can double the force experienced by a user. Muscles and ligaments can be damaged by this inertia-generated overload. To avoid injuries coaches and therapists prefer resistance to remain constant throughout the range and speed of a user’s movement. Since there are no weights used in PST, there is no inertia, nor any of its negative side effects. A user can be assured that, no matter what movement is made, the resistance remains constant. Compressed air systems have been designed with the same advantage in mind, they however succeed to a lesser degree to achieve true constant friction.

SPACE SAVING, LIGHTWEIGHT MACHINE

PST allows for a reduced footprint. It will fit in a box of 1400x800x200 mm for a machine that is capable of delivering a 140kg load equivalent, while weighing only 40kg. Smaller load range

requirements will further reduce size and weight.

FREEDOM IN MACHINE DESIGN

PST is not dependent on gravity. The orientation of the system, relative to the forces of gravity, has

no influence on its function. This makes a larger variety of system layouts possible and creates more

freedom in design. Moreover, the load interface of the PST can be positioned in a variety of places best suitable to the overall system layout, contributing to design freedom and machine ergonomics.

COMPLETELY STAND-ALONE

In contrat to compressed air systems PST is a complete stand-alone system. There is no need for

additional infrastructure or energy supply.

LONG SERVICE LIFE, LOW MAINTENANCE

PST consists of very basic, easily replacable, mechanical components, and has proven to achieve millions of cycles without maintenance.

STEPLESS ADJUSTMENT OF LOAD

PST can exert a load equivalent of 2 to 300kg, comparable to existing weight-based machines. An

advantage is the possibility to adjust the increments between loads. Precise increments of for example,

0.5 kg, 2 kg or 5 kg are all possible, and can be predesigned. With the addition of an actuator it is even possible to make the load continuously adjustable.

LOW COST AUTOMATION

PST allows for easy automation of load adjustment, since the adjustment requires very little energy

or movement. The simplest of actuators and electronic interfaces can facilitate such adjustments in very little time (<0,5s). This will make it easy and cost efficient to combine the system with electronic

equipment, while at the same time enabling more freedom in design.

COST COMPETITIVE TECHNOLOGY

PST is cost competitive in comparison to conventional constant resistance solutions.